Update: 4th axis completed. This will run at a max of 1,300 RPM or 2,000 RPM depending upon which motor pulley is used. Should be able to run all day long at top speed. There is a steel part that I make from 3/4" 12L14 steel at 1,800 RPM. it has 1/4-28 internal threads and flats on each side. This final iteration of the 4th axis will be expected to turn, drill, tap and cut the flats using one continuous program. We shall see . . . .

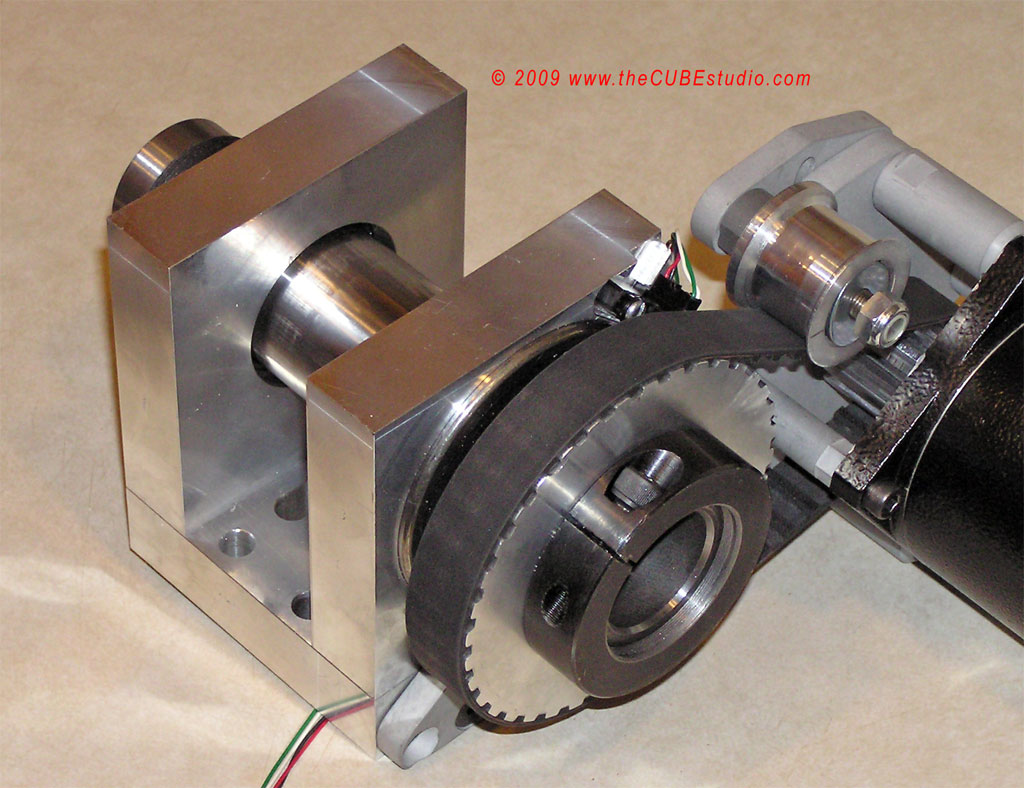

Basic drive parts moved over from previous prototype:

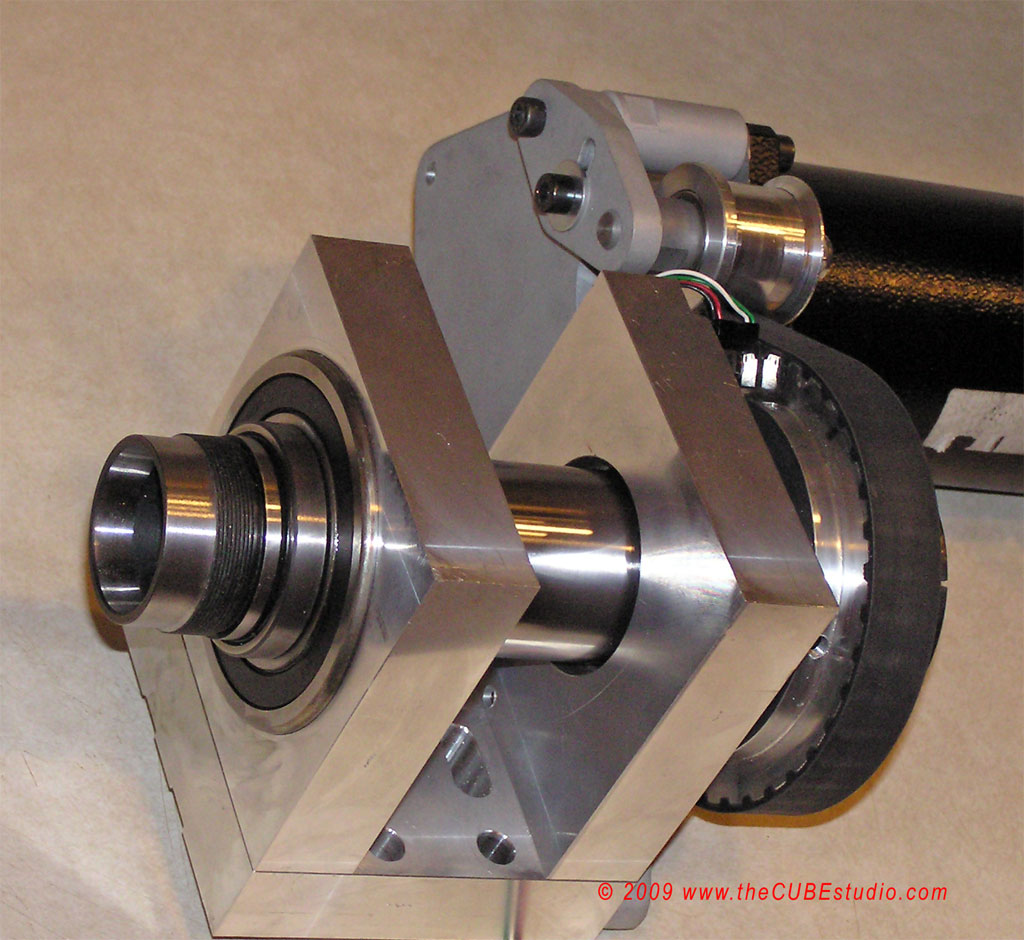

Final assembly:

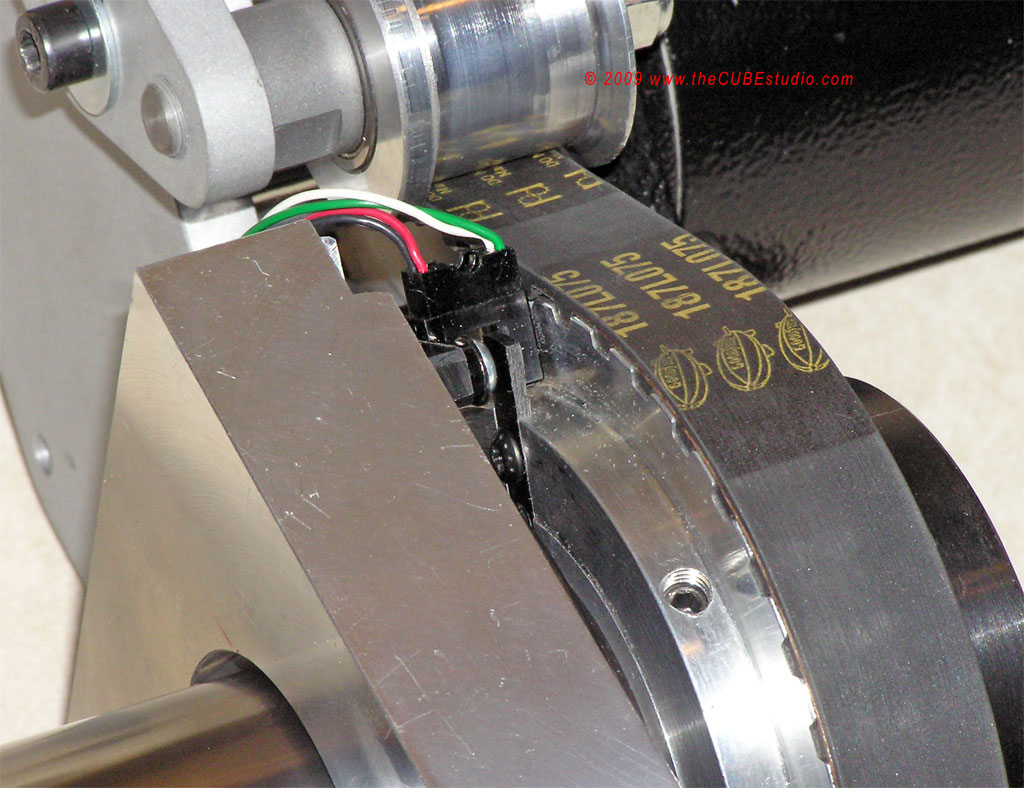

Homing sensor moved to back and oriented down to keep out as much swarf as possible.

I have my new Rutex servo drive and so far it is doing everything it claims to do, so I should get full speed and power from the motor. When I get it all back on the mill, I will make one final video and post the link. Questions, comments , criticisms or suggestions welcome.