So, I got a nice new .125" ball nose end mill and set about running the Circular Pocket Wizard.

After making a few dimensional alterations to fit my stock and machine, I hit the "GO" button.

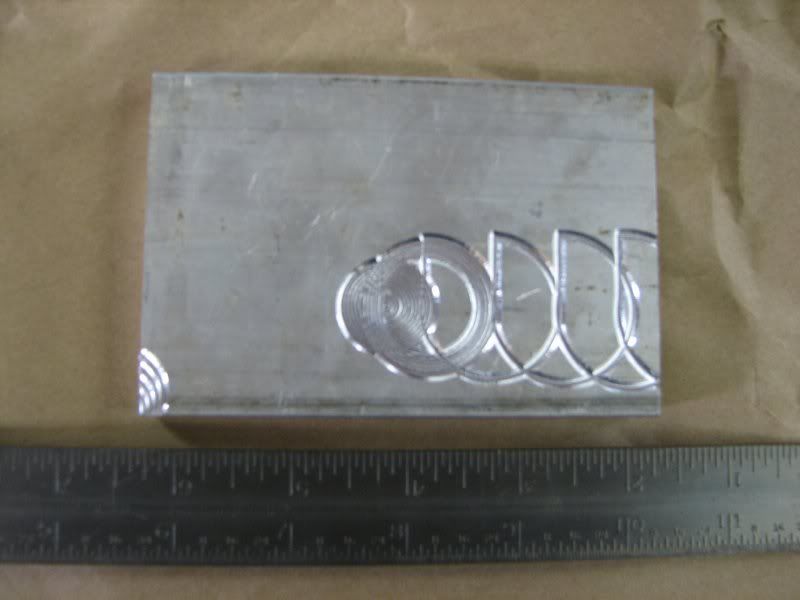

Things were progressing nicely on the initial pass until it reached approximately 3/4", and then things started getting weird.

You can see what happened in the pic.

Changes I made in the Wizard were: setting the tool diameter and stepover percentage, reducing the overall diameter of the pocket to 1.5", reducing the overall depth to .500", as well as feed rate.

I removed the end mill, homed the axes and hit the "GO" button again with essentially the same result cutting air.

The machine is a Dyna Myte 2400 using the OEM steppers and drivers through a SmoothStepper and a Probotix breakout board.

Anyone have any ideas on where to start trouble shooting?

Rex