ok, i have been spending a little more time with the machine. i think the steps per unit for the y axis were off, and still are a little bit, but i am getting pretty close.

i have been working on getting a good drawing test, had to spend some time rigging up a pen mount, i think i have something workable for now.

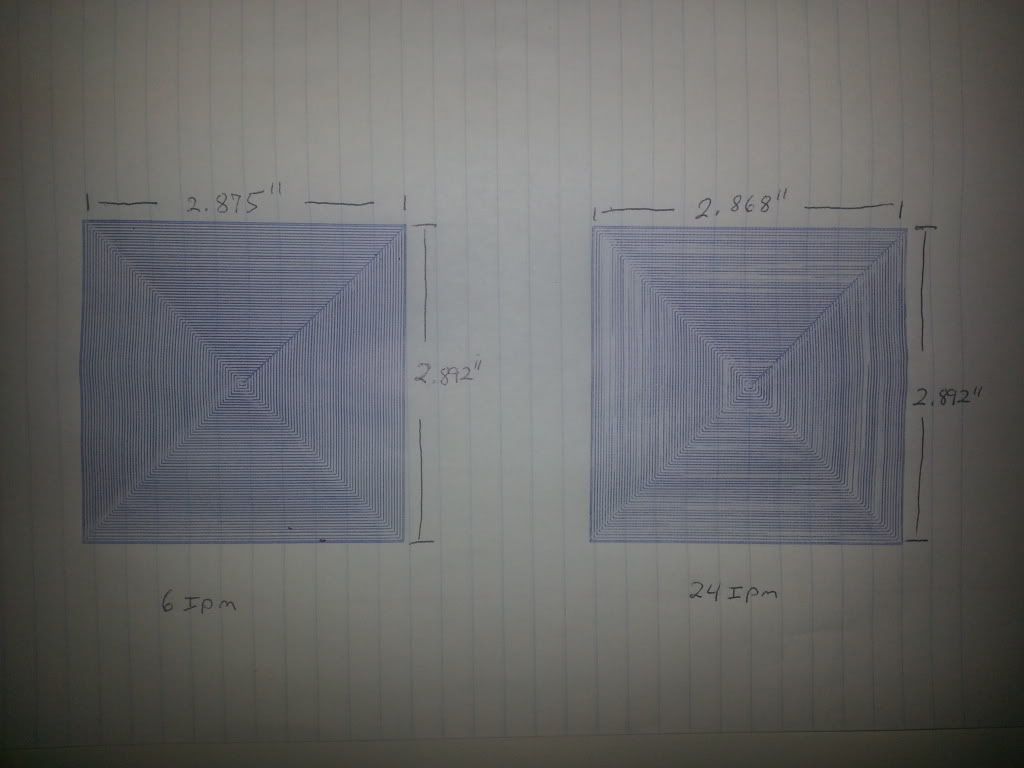

here is a good example of the drawing test.

the g code is for a 1/8" end mill 3" square pocket, so the magic number should be 2.875" which the x axis is dead on in the left square.

i think several things happened on the right one.

the x axis motor was getting very hot.

the x axis did not move very smoothly at that speed.

the pen did not write as well at that speed.

as you can see in both the y axis is not quite the correct size. now the x axis (the one that is perfect) is a direct drive from the motor, while the y has a belt drive gear reduction. i am trying to determine if there is some backlash in that setup. any tips on how to measure this or work it out are welcome!